WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Screen Brushy Creek Crushing Circuit Rod Mill Ore from Underground Reclaim Ore Secondary Crusher Fines Chute Vibratory Feeder Oversize Ore Through Crusher Fine Ore (minus 5/8") Fine Ore (minus 5/8") To Rod Mill Grinding Brushy Creek Grinding Circuit Rod Mill Ball Mill Cyclone Feed Sump 4 Cyclones Cyclone Feed Pump Water Discharge Water ...

PREDICTING NICKEL RECOVERIES AT THE THOMPSON MILL FROM FEED MINERALOGY F.D. Ford1, Z. Dai1 and A. Byers (P.Eng.)2 1 Vale Base Metals Technical Excellence Center Mineralogy and Mineral Processing ...

Aug 17, 2018· Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles. Rod mills can accept feed up .

Finely disseminated ores require substantial comminution costs to liberate the valuable minerals. In 1986, it was estimated that 35% of selling price for copper was associated with the crushing and grinding of host ore. A copper mine, image courtesy of Aibyek Khamkhash [image 135 .

YEARS OF OPERATION OF THE SAG/BALL MILL GRINDING CIRCUIT AT PHU KHAM COPPER, GOLD OPERATION IN LAOS. ... ore from the stockpile to the SAG mill feed conveyor.. The discharge from the SAG mill is screened by a ... Design Bond Rod Mill WI (closing 1180 micron) Refer Table 2 Circuit Fresh Feed Rate - Nominal 1,500 tph ...

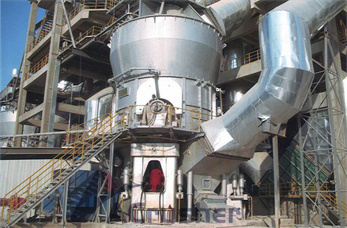

A wet autogenous mill that materials as grinding media Feeding Particle Size 200-350mm Product improvement High-efficiency autogenous mill can realize the second and third stage crushing and screening, and part or all crushing and grinding of rod mill or ball mil. Low power consumption, no dust pollution, less auxiliary equipment, easy ...

Grinding and Flotation. Fine ore at minus 19mm (¾") sizing is fed at a controlled rate into the open-circuit 2600mm x 3960mm (8'-6 x 13'-0) Hardinge rod mill at an average feed .

Ball/Rod mill Literature The Ball/Rod mills are meant for producing fine particle size reduction through attrition and compressive forces at the grain size level. They are the most effective laboratory mills for batch-wise, rapid grinding of medium-hard to very hard samples down to finest particle sizes.

Rod mills accept feed up to about 50 mm (2 in.) and produce a product in the size range of 3000 to 270 mm (4 to 35 mesh). Rod mill is widely applied in metal and nonmetal mine, water conservancy, glass and construction materials industries, mainly suitable for grinding various ores .

The rod mill work index laboratory test is conducted by grinding an ore sample prepared to 80% passing 12.7 mm (½ inch, the original test being developed in imperial units) to a product size of approximately 1 mm (in the original and still the standard, 14 mesh; see Chapter 4 for definition of mesh), thus determining the rod mill work index ...

Jun 19, 2015· If 75 percent of critical speed is considered desirable for efficient grinding in a 2.4 meter (8 foot) diameter mill, then the same will be true for a 5.0 meter (15½ foot) diameter mill.

supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® high-pressure grinding roll. SAG and ball mill for gold ore grinding. One of three SAG mills with 9.75 m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran.

of the feed on comminution effects in rod and ball mills in laboratory scale 2.1. Methodology of investigation The purpose of the research was to determine the comminution levels and increase of the finest fractions for ore by influence of dry grinding in rod and ball mills in various grinding times according to scheme presented on Figure 1.

Figure 8.2 Media motion in the tumbling mill. 8.1 Grinding 8.1.1 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types - rod, ball, pebble autogenous and semi-autogenous. ... or large lumps of ore in an autogenous mill or a mixture in ...

The article concerns issues related to the copper ore ball mill grinding process, operating at different technological parameters. The aim of the study was to investigate the influence of various ...

RTB Bor, Serbia: Copper ore production up, processing costs down. Together with , the Serbian RTB Bor mine renewed the processing plant at its largest site, Veliki Krivelj. The result was a higher throughput and better recoveries with less energy consumption per ton of processed copper.

F 80 is the mill circuit feed size in micrometers. Rod mill. A rotating drum causes friction and attrition between steel rods and ore particles. [citation needed] But note that the term 'rod mill' is also used as a synonym for a slitting mill, which makes rods of iron or other metal. Rod mills are less common than ball mills for grinding minerals.

Grind coarse feed material with a reliable Rod Mill that won't over-grind. If you are in need of an application for coarse materials like limestone, potash, coal, phosphate and bauxite, you may be looking for a solutions like Rod Mills. Rod Mills are particularly useful, if you run a low tonnage operation and are looking for coarse product.

Copper Ore Processing Methods 911 Metallurgist. Apr 11, 2017 The milling of copper ores as practiced in the larger concentrators has changed to such an extent that comparatively few of the machines in use at the The rapid development of ball-mill grinding must also be attributed to the adoption of the flotation process, since it was the incentive for developing

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energy-saving ball mill up to 30%, great ball mill working principle, which greatly reduces the cost of the ore .

air separator mill with drying chamber for iron ore grinding. The single-compartment mill is ideal for the grinding of fine-grained feed material. One typical application is the combined grinding and drying of iron ore concentrate with a high feed moisture content (up to approx. 8 %). High-efficiency separators minimise the power consumption of ...

Gold ore concentration plant. gold ore gravity concentration plant for small scale miners. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including quarry, aggregate, and different kinds of minerals.

copper roligmill Feldspar Crusher Sales XSM machinery. copper roligmill. copper roligmill XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (copper roligmill) in more than one hundred of the worldsales of countries and regions.

Semi-Autogenous Grinding Mill Specifi c Energies Using a Combination of Bond Work Indices and Julius ... size than an ore with a 3.5 SG. This fact is not evident in the ... the rod mill feed is produced from an open circuit crusher the factor to be applied increases to 1.4.